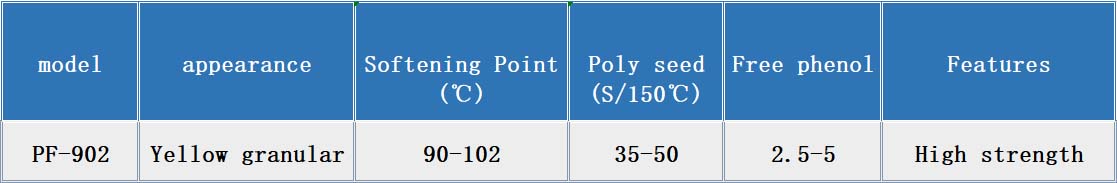

Electric wood powder resin

The main raw materials for electric wood powder and glued wood powder

View Details

Electric wood powder resin

Electric wood powder resin is the main raw material in electric wood powder (bakelite powder).

The following is a detailed explanation of electric wood:

-

Basic Attributes:Phenolic resin, as the raw material for producing electric wood powder or bakelite powder, is mainly black. Products sold in the market often contain coloring agents, resulting in various colors such as red, yellow, black, green, brown, and blue. Its form can be granular or powdery.

-

chemical property:Electric wood resin is resistant to weak acids and weak bases, but it will decompose when exposed to strong acids and corrode when exposed to strong bases. It is soluble in organic solvents such as acetone and alcohol.

-

physical property:Solid phenolic electric wood resin is a yellow, transparent, amorphous block like substance that may appear slightly red due to the presence of free phenols. Its average specific gravity is around 1.7, easily soluble in alcohol and insoluble in water. Stable to water, weak acid, and weak base solutions.

-

Preparation process:Electric wood resin is a resin made by the condensation of phenol and formaldehyde under catalytic conditions, and DMJ. According to the different catalysts selected, phenolic resins can be divided into two categories: thermosetting and thermoplastic.

-

application area :

Anti corrosion engineering:Electric wood has a wide range of applications in anti-corrosion engineering due to its excellent acid resistance.

an adhesive:Phenolic resin can be used as a raw material for adhesives and is used for bonding various materials.

Flame retardant material:Electric wood has excellent flame retardant properties and is often used as a component of flame retardant materials.

Grinding wheel manufacturing:Electric wood also plays an important role in the manufacturing of grinding wheels.